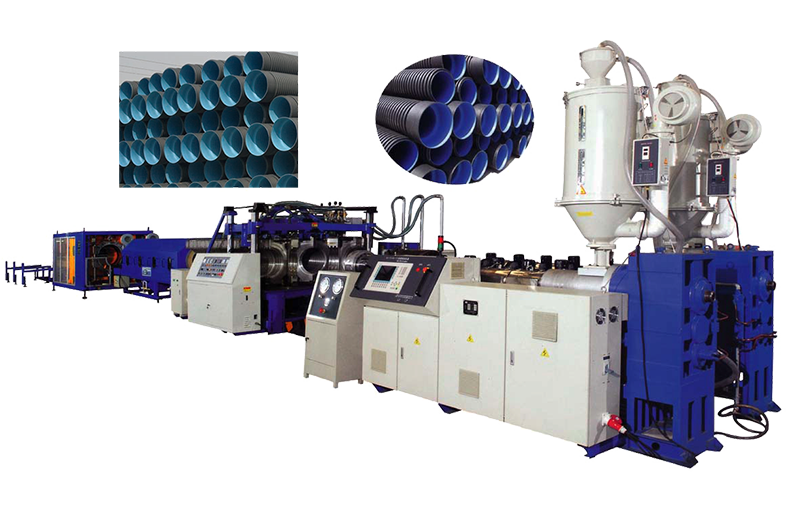

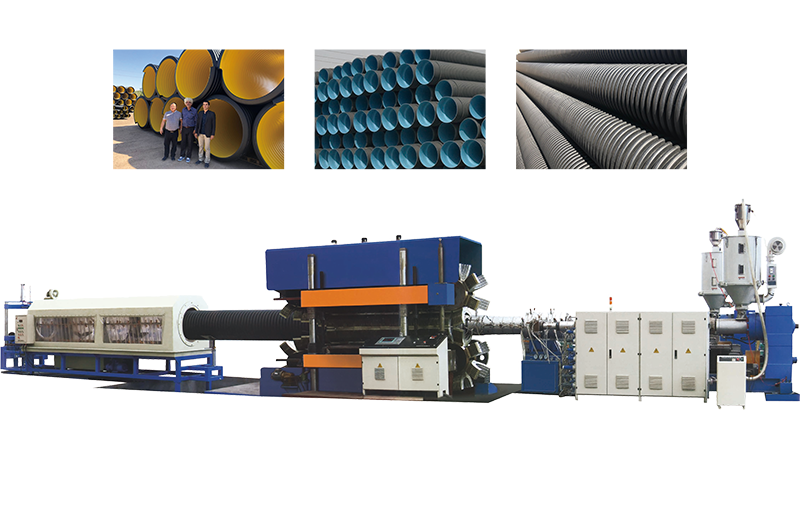

High Speed PE PP (PVC) Corrugated Pipe Extrusion Line

Tlhaloso

Mochini oa lipeipi tsa polasetiki tse entsoeng ka masenke o sebelisetsoa ho hlahisa lipeipi tsa masenke tsa polasetiki, tse sebelisoang haholo litsing tsa metsi tsa litoropo, lits'ebetso tsa likhoerekhoere, merero ea litsela tse kholo, merero ea nosetso ea metsi a masimong, hape e ka sebelisoa mererong ea lipalangoang tsa mokelikeli oa lik'hemik'hale, ka mefuta e mengata e fapaneng ea lits'ebetso. Mochini oa ho etsa lipeipi tse nang le makotikoti o na le melemo ea tlhahiso e phahameng, extrusion e tsitsitseng le boemo bo phahameng ba boits'oaro. Extruder e ka etsoa ho latela maemo a khethehileng a lisebelisoa tsa mosebedisi, joalo ka PE PP kapa PVC. PE PP e nang le mabota a mabeli a marang-rang a marang-rang a extrusion a sebelisa mofuta o mocha oa lisebelisoa tse phahameng tsa "single/twin screw extruder". Mochini oa peipi ea masenke oa PVC o sebelisa mafahla a maholo a bataletseng kapa mafahla a conical extruder. Ka lera le le leng le mekhahlelo e 'meli bakeng sa khetho. Ho etsa liphaephe tse entsoeng ka marako a mabeli, ho na le mefuta e 'meli,rapameng habeli leboteng masenke phala extrusion molalepaatsepama habeli leboteng masenke phala extrusion mola.

Phallo ea Ts'ebetso

Lintho tse tala → Ho kopanya → Setsi sa Vacuum → Sehoma sa Plastic Hopper →Extruder → Extrusion Mould → E Etsa Mould→ Mochini o pholileng oa metsi →Fafatsa Tanka ea Metsi a Pholisang → mochini o sehang →Stacker

Likarolo le Melemo

1. HDPE e amohela mofuta o mocha oa lisebelisoa tse phahameng tsa "single / twin screw extruder", 'me PVC e amohela mafahla a maholo a sephara kapa mafahla a conical extruder. Big conical twin-screw extruder kapa parallel twin-screw extruder e ka hlokomela polasetiki e ntle ka mocheso o tlase le extrusion e tsitsitseng.

2. Mokhoa oa ho pholile oa module o qobelloa ho pholile ha metsi, e leng ho ntlafatsang haholo lebelo la ho pholile la module, e le ho finyella tlhahiso e phahameng ka potlako.

3. Mohala oa liphaephe tse nang le likoti tse boetseng o bitsoa habeli lebota la mochini oa phala ea sekoti o ka lemoha ho phatloha ha marang-rang ho netefatsa hore thepa e sa tšoaneng ea phala e entsoeng e finyella litekanyetso.

4. Li-valve tse fetolang karo-karolelano tse tsoang linaheng tse ling li fetola ho etsa khatello e tsitsitseng le e ka tšeptjoang.

5. Horizontal mofuta corrugator

6. Plateform e sebetsang e ka fetoloa ka mahlakore a mararo.

7. Sistimi ea ts'ireletso ea othomathiki ea qala mme e sebetsang ea khutla ha motlakase o tima.

8. Seteishene sa ho lubrication ka boiketsetso

9. Li-blocks tsa hlobo li entsoe ka alloy e khethehileng ea aluminium 'me e na le boima bo bobebe, matla a phahameng, ho se mamelle ho apara hantle, ho sebetsa hantle ha mocheso o monyenyane oa ho atolosa mocheso.

10. Pholiso ea moea le pholileng ea metsi bakeng sa liforomo tsa masenke tse pholileng tse etsang liphaephe kapele.

11. Mochini oa ho seha lipeipi tsa masenke o na le melemo ea ho nepahala ho phahameng ebile ha o na lerōle.

12. Mohala o feletseng o amohela tsamaiso ea PLC ea micro-computer e khonang ho bonts'a mocheso oa ho qhibiliha le khatello, ho etsa lebelo, alamo ea phoso hape e na le bokhoni ba polokelo ea ts'ebetso ea motheo.

Lintlha

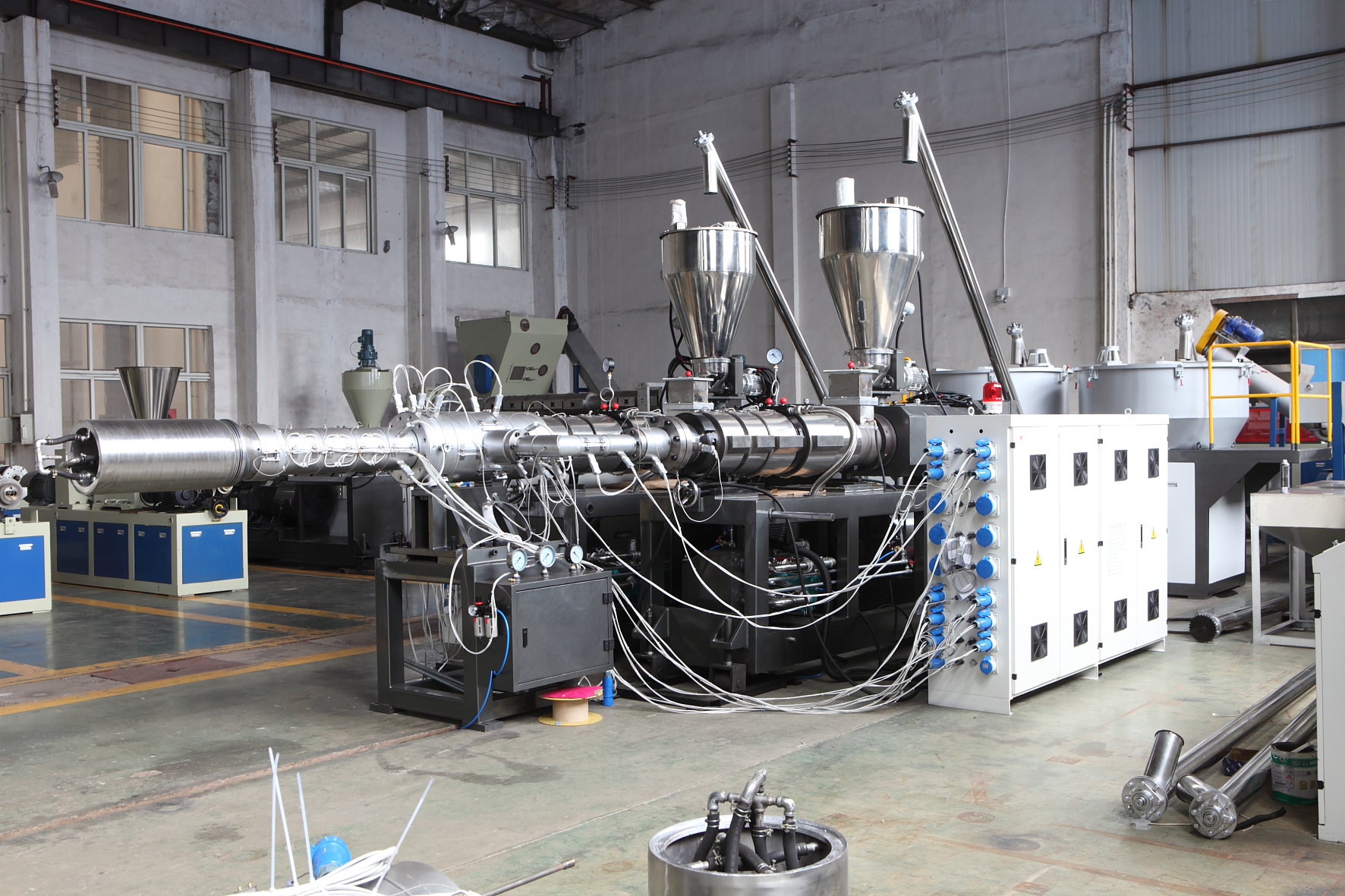

Single Screw Extruder bakeng sa PE/PP

Ho latela karo-karolelano ea 33: 1 L/D bakeng sa moralo oa screw, re thehile karolelano ea 38: 1 L/D. Ha ho bapisoa le karo-karolelano ea 33: 1, karolelano ea 38: 1 e na le monyetla oa ho etsa polasetiki ea 100%, e eketsa matla a tlhahiso ka 30%, e fokotsa tšebeliso ea matla ho fihla ho 30% mme e fihlella ts'ebetso e batlang e lekana. Adopt L/D ratio 38:1 screw for virgin material le L/D 33:1 screw for material recycled.

Simens Touch Screen le PLC

Etsa kopo ea lenaneo le ntlafalitsoeng ke k'hamphani ea rona, u be le Senyesemane kapa lipuo tse ling ho kenya letsoho tsamaisong.

Sebopeho sa Spiral sa Barrel

Ho fepa karolo ea barrel ho sebelisa sebopeho sa spiral, ho etsa bonnete ba hore phepo ea lintho tse bonahalang e tsitsitse le ho eketsa matla a ho fepa.

Moqapi o Khethehileng oa Screw

Screw e entsoe ka sebopeho se ikhethileng, ho netefatsa hore polasetiki e ntle le ho kopanya. Lintho tse sa qhibilihisitsoeng li ke ke tsa feta karolo ena ea screw.

Air Cooled Ceramic Heater

Ceramic heater e netefatsa bophelo bo bolelele ba mosebetsi. Moralo ona ke ho eketsa sebaka seo heater e kopanang le moea. Ho ba le phello e ntle ea ho pholisa moea.

Gearbox ea boleng bo holimo

Ho nepahala ha gear ho lokela ho netefatsoa ka grade 5-6 le lerata le tlase ka tlase ho 75dB. Sebopeho se kopaneng empa se na le torque e phahameng.

Conical Twin Screw Extruder bakeng sa PVC

Ka bobeli conical twin screw extruder le parallel twin screw extruder e ka sebelisoa ho hlahisa PVC. Ka theknoloji ea morao-rao, ho theola matla le ho netefatsa bokhoni. Ho latela foromo e fapaneng, re fana ka moralo o fapaneng oa screw ho netefatsa phello e ntle ea polasetiki le bokhoni bo phahameng.

Extrusion Mold

Ka bobeli lera ka ntle le lera le ka hare li extruded ka hare ho hlooho ea lefu. Mocha o mong le o mong oa phallo ea thepa ka hare ho hlooho ea lefu o behoa ka tsela e lekanang. Mocha o mong le o mong ke ka mor'a phekolo ea mocheso le ho bentša seipone ho netefatsa hore thepa e phalla hantle. Hape shoa hlooho e fana ka moea o petelitsoeng pakeng tsa lera ka bobeli. Sleeve ea calibration e sebelisetsoa ho pholisa lesela le ka hare ho etsa phala e boreleli le e bataletseng ka hare. Khatello ea metsi e phalla ka har'a sleeve ea calibration ho ba le phello e ntle ea ho pholisa. Vacuum e entsoe holim'a sleeve ea calibration ha e hlahisa phala e kholo ea bophara, e netefatsa hore lipeipi li pota-potile.

Ho theha hlobo

CNC machining e netefatsa litekanyo tse nepahetseng. Setsi sa moea sa vacuum le mocha o pholileng oa metsi o nang le phallo e kholo ea phallo e netefatsang ts'ebetso e tsitsitseng, ea boleng bo phahameng le e sebetsang hantle. Lisebelisoa tsa mojule ke alloy ea aluminium e matla haholo, e nang le conductivity e phahameng ea mocheso, boima bo phahameng, le ho hanyetsa ho apara ho phahameng. Sebopeho sa li-module se nka mokhoa oa bohlokoa oa ho lahla khatello, ka sebopeho se teteaneng le botsitso bo phahameng ba mocheso. Kalafo e ka hare ea holim'a mojulu e ntlafatsa matla le boima ba mojule, e leng ho loketseng haholoanyane ho thehoa ha li-ripples. Mofuta o amohela mochini oa CNC ho netefatsa ho nepahala le ts'ebetso ea ona hantle.

Mochine o pholisang oa metsi Ho theha mochini

Mochini o pholileng oa metsi o sebelisetsoa ho beha le ho tsamaisa hlobo e entsoeng ka masenke, vacuum e etsoa ho monya bokantle bo ka har'a hlobo e entsoeng ka masenke ho etsa sebopeho sa masenke. Ka ho tsamaisa hlobo e entsoeng ka masenke, phala e boetse e ntšoa ka har'a sekoti.

Automatic Lubrication System

Tlosa likere ka boits'oaro ho etsa hore hlobo ea masenke e tsamaee hantle.

Phetiso ea Gear Rack

Gear rack e behoa ka holim'a hlobo e entsoeng ka masenke. Li-racks tsohle tsa lisebelisoa ke ka mor'a phekolo ea nitriding le ho futhumatsa, ho hanela ho apara nako e telele.

Sistimi ea Phetoho e Phahameng

Lokisa foreimi e ka holimo ka mokhoa oa elektronike bakeng sa boholo bo fapaneng ba hlobo e entsoeng ka masenke. Ka litšiea tse 'nè, netefatsa phetoho e tsitsitseng le e nepahetseng.

Sistimi ea ho fetola tsitsipano

Ho lokisa boima ba hlobo, etsa hore hlobo e tsamaee hantle.

Seqhubu se lekanang

Ho laola moea o tsitsitseng haholoanyane le o nepahetseng, ho theha phala e ntle le sebopeho sa sokete.

Mold Cooling System

Ka bobeli tsamaiso ea ho pholisa metsi le moea, ho ba le phello e ntle ea ho pholisa, ho etsa lipeipi tse ntle le tse potlakileng.

UPS Backup Power

Ha motlakase o hloleha, matla a bekapo a UPS a tla fana ka matla ho corrugator ho ntša phaephe ho tsoa letsohong la calibration. Ho qoba peipi e khomaretsoeng holim'a sleeve ea calibration ka mor'a hore phala e pholile le ho honyela.

Fafatsa Tanka ea Metsi a Pholisang

Tanka e futhumatsang e sebelisetsoa ho pholisa phala ho feta.

Thuso ea ho hula ka thata

Ka sesebelisoa sa ho hula se thusang, sesebelisoa sa ho hula le sona sea fetoha. Ho hula phala ho feta.

Quality Spray Nozzle

Li-nozzles tsa boleng bo botle li na le phello e ntle ea ho pholisa, 'me ha ho bonolo ho thijoa ke litšila.

Sefe ea Tanka ea Metsi

Ka sefe ka tankeng ea metsi, ho qoba litšila tse kholo ha metsi a ka ntle a kena.

Mochini oa ho seha lipeipi tse entsoeng ka masenke

Mochini oa ho seha lipeipi tsa masenke o nepahetse haholo ebile ha o na lerōle.

Sesebelisoa sa Aluminium Clamping

Kenya sesebelisoa sa aluminium clamping bakeng sa boholo bo fapaneng ba liphaephe. Saese e 'ngoe le e' ngoe e nang le sesebelisoa sa eona sa clamping, ha ho na tlhoko ea ho fetola bophahamo bo bohareng ba liphaephe tse fapaneng.

Sistimi ea khokahano

Seteishene sa ho itšeha se tsamaisoa ke enjene le inverter. Nakong ea ts'ebetso ea ho itšeha, seteishene sa ho itšeha se tsamaea ka mokhoa o ts'oanang le corrugator ho qoba deformation ea pipe.

Ho Seha Lithipa Habeli

Ka lithipa tse peli tse sehang hammoho, ho etsa bonnete ba hore karolo e qetellang ea sokete e khaotsoe ka botlalo.

Stacker

Ho tšehetsa le ho theola lipeipi. Bolelele ba stacker bo ka etsoa ka mokhoa o ikhethileng.

Ho tšehetsa le ho theola lipeipi. Bolelele ba stacker bo ka etsoa ka mokhoa o ikhethileng.

E le ho tsamaisa peipi ea masenke hantle holim'a stacker, re sebelisa tšepe e sa hloekang holim'a stacker.

Ho kenya phala ho rolara, ho bonolo ho e boloka le ho e tsamaisa. Hangata e sebelisetsoa phala e ka tlase ho boholo ba 110mm. E-ba le seteishene se le seng le liteishene tse habeli bakeng sa khetho.

Lintlha tsa Tekheniki

| Mohlala | Boholo ba phala(mm) | Extruder | Sephetho(kg/h) | Lebelo(m/min) | Kakaretso ea matla(KW) | Hlobo(para) | Sistimi ea ho pholisa |

| SGB250 | 90-250 | SJ65 SJ75 | 300 | 1-4 | 150 | 48 | Ho pholisa moea le ho pholisa metsi |

| SGB500 | 200-500 | SJ75 SJ90 | 600 | 1-4 | 200 | 40 | Ho pholisa moea le ho pholisa metsi |