Methapo e meng ea extrusion ea lipeipi ea rekisoa

Mochini oa lipeipi oa tšepe o matlafalitsoeng ka terata ea tšepe

Steel wire skeleton reinforced plastic composite pipe machine e sebelisoa haholo indastering, phepelo ea metsi a toropo, khase, lik'hemik'hale le temo, joalo-joalo Mohala ona o ka sebelisa mohala o matla oa tšepe, khalase ea fiber le PET ho hlahisa phala e matla ea polasetiki e kopantsoeng. E ka hlahisa metsi a polyethylene kapa pipe ea khase hape. Ke merero e mengata ho boloka matsete. Pipe e na le monyetla oa khatello e phahameng, lisebelisoa tse sa hlokahaleng le tse sa tsitsang, tec. Tekanyetso e ile ea sebelisoa 'me ea kenngoa ts'ebetsong ka selemo sa 2004. Melao le litlhophiso tsa boenjiniere li phethiloe hantle. Tlhahiso, thekiso le khothaletso e bile mohato ka mohato tseleng ea ntlafatso ea indasteri. E fetoha sehlahisoa se seholo sa liphaephe tse kopantsoeng.

Letsatsi la Tekheniki

| Mohlala | Bophahamo ba Lipeipi(mm) | Lebelo la mohala(m/min) | Kakaretso ea Matla a Kenyeletso(kw |

| LSSW160 | 中50- φ160 | 0.5-1.5 | 200 |

| LSSW250 | φ75- φ250 | 0.6-2 | 250 |

| LSSW400 | φ110- φ400 | 0.4-1.6 | 500 |

| LSSW630 | φ250- φ630 | 0.4-1.2 | 600 |

| LSSW800 | φ315- φ800 | 0.2-0.7 | 850 |

| Boholo ba Pipe | Pipe e tiileng ea HDPE | Mesapo ea terata ea tšepe e matlafalitsoeng ka phala e entsoeng ka polasetiki | ||

| Botenya(mm) | Boima ba 'mele(kg/m) | Botenya(mm) | Boima ba 'mele(kg/m) | |

| φ200 | 11.9 | 7.05 | 7.5 | 4.74 |

| φ500 | 29.7 | 43.80 | 15.5 | 25.48 |

| φ630 | 37.4 | 69.40 | 23.5 | 40.73 |

| φ800 | 47.4 | 112.00 | 30.0 | 75.39 |

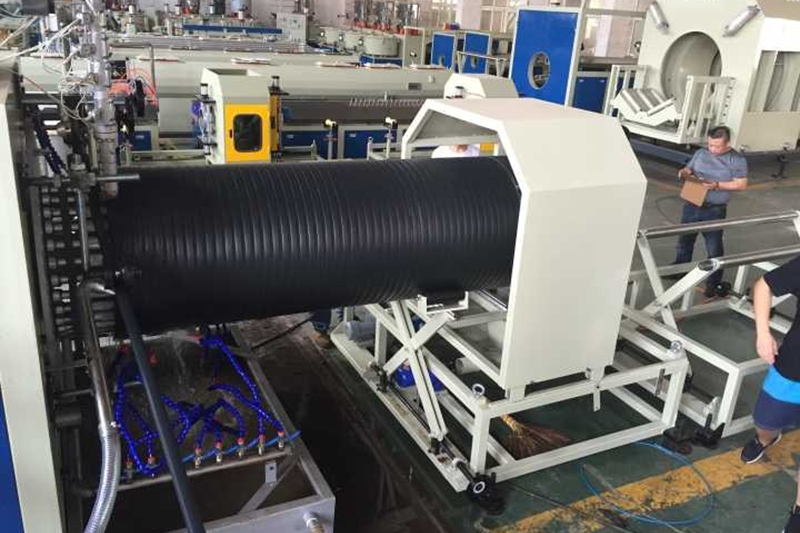

HDPE sekoti leboteng matsoelintsoeke mochini phala

Mochini oa liphaephe oa HDPE o se nang letho o sebelisetsoa ho etsa liphaephe tse sebelisetsoang ho tsamaisa metsi le likhoerekhoere masimong a mangata, joalo ka kaho ea masepala, litereke tsa bolulo, litsela tse kholo le marokho, joalo-joalo.

Hollow lebota matsoelintsoeke phala e haholo-holo sebelisoa bakeng sa tsamaiso ea likhoerekhoere, e tšoanang le habeli lebota masenke phala. Ha e bapisoa le phala e entsoeng ka marako a mabeli, e na le melemo ea theko e tlaase ea lichelete tsa mochine le bophara bo boholo ba phala.

Mohala oa rona oa PE hollow winding extrusion pipe o ka sebetsana le mefuta e mengata ea thepa, ho kenyeletsoa HDPE, PP, joalo-joalo, boholo ho tloha bonyane ba 200mm ho isa ho 3200mm ka lera le le leng kapa lera le lengata.

Ho fetola likarolo tse ling ho ka hlahisa sebopeho se fapaneng sa phaephe kapa profaele ho etsa mefuta e fapaneng ea phaephe ea spiral.

◆The extruder ea pele e hlahisa phala e khutlonnetsepa ka har'a mochini o etsang matsoelintsoeke, ea bobeli e hlahisa bareng ea polasetiki, ebe polasetiki e hatelloa holim'a phala e khutlonnetsepa le liphaephe tse matsoelintsoeke.

◆E amohela spiral die head le tse peli tse extruder charger, ho hlokomela spiral rotational forming.

◆Sistimi e tsoetseng pele ea taolo ea komporo ea PLC e etsa hore ho be bonolo ho sebetsa. E tsitsitse ebile e ka tšeptjoa.

◆ Ka moralo o fapaneng oa profil tube e ka hlahisa liphaephe tsa dfrerent ring stfness tse audapt todiferet maemo le felds.

◆E na le bokgoni bo phahameng ba sekrufuru se le seng (re sebelisa gramule) le screwextruder e bolokang matla (ho sebelisa phofo kapa granule material forchoice.

◆ Ho fetola likarolo tse ling ho ka boela ha hlahisa phala ea tšepe ea proftle e matlafalitsoeng.

◆ Tlhaloso e feletseng ea litlhaloso, palo ea liphaephe: ID200mm -ID3200om

Lintlha

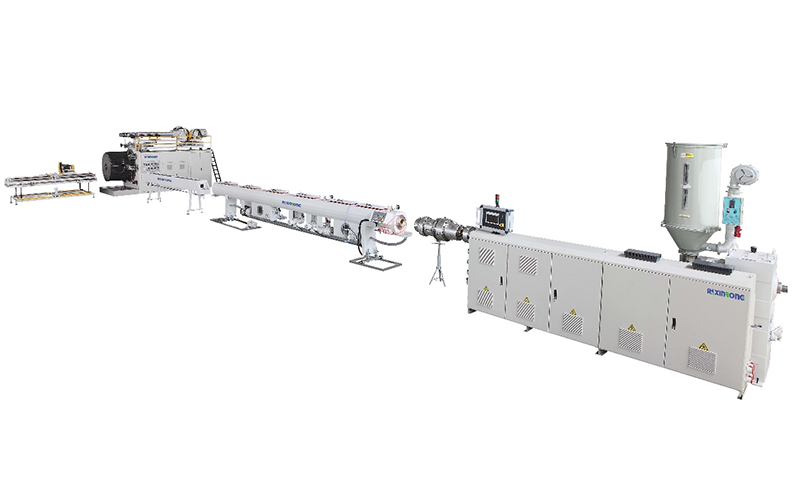

Single Screw Extruder

Ho latela karo-karolelano ea 33: 1 L/D bakeng sa moralo oa screw, re thehile karolelano ea 38: 1 L/D. Ha ho bapisoa le karo-karolelano ea 33: 1, karolelano ea 38: 1 e na le monyetla oa ho etsa polasetiki ea 100%, e eketsa matla a tlhahiso ka 30%, e fokotsa tšebeliso ea matla ho fihla ho 30% mme e fihlella ts'ebetso e batlang e lekana.

Simens Touch Screen le PLC

Etsa kopo ea lenaneo le ntlafalitsoeng ke k'hamphani ea rona, u be le Senyesemane kapa lipuo tse ling ho kenya letsoho tsamaisong.

Sebopeho sa Spiral sa Barrel

Ho fepa karolo ea barrel ho sebelisa sebopeho sa spiral, ho etsa bonnete ba hore phepo ea lintho tse bonahalang e tsitsitse le ho eketsa matla a ho fepa.

Moqapi o Khethehileng oa Screw

Screw e entsoe ka sebopeho se ikhethileng, ho netefatsa hore polasetiki e ntle le ho kopanya. Lintho tse sa qhibilihisitsoeng li ke ke tsa feta karolo ena ea screw.

Air Cooled Ceramic Heater

Ceramic heater e netefatsa bophelo bo bolelele ba mosebetsi. Moralo ona ke ho eketsa sebaka seo heater e kopanang le moea. Ho ba le phello e ntle ea ho pholisa moea.

Gearbox ea boleng bo holimo

Ho nepahala ha gear ho lokela ho netefatsoa ka grade 5-6 le lerata le tlase ka tlase ho 75dB. Sebopeho se kopaneng empa se na le torque e phahameng.

Mochini o fefolang moea

Mochini o etsang matsoelintsoeke o sebelisetsoa ho fefola phala ea lisekoere ebe o li kopanya ho etsa phaephe ea spiral. E ka fetoha ho hlahisa boholo bo fapaneng ba liphaephe tsa spiral, hape lengeloi la matsoelintsoeke le khona ho fetoha bakeng sa phala ea lisekoere ka bophara bo fapaneng. Ka ho pholisa metsi ka katleho.

Sekhomaretsi Extruder

Ka sekhomaretsi extruder ho beha ka holimo ho matsoelintsoeke mochine. Extruder e ka tsamaea ka mahlakoreng 'ohle: pele le morao, holimo le tlase, ho le letšehali le ka ho le letona. Ho bonolo ho sebetsa.

Felletse tsamaiso ea tokiso

Sete e felletseng ea sistimi ea ho lokisa ho etsa hore phala e sekoere e be bonolo ebile e tsitsitse.

Gear Drive

Sebelisa koloi ea lisebelisoa, mochini o tsoelipanang o sebetsa o tsitsitse, o nepahetse ebile o sebetsa hantle.

Siemens PLC

Etsa kopo ea lenaneo le ntlafalitsoeng ke k'hamphani ea rona, u be le Senyesemane kapa lipuo tse ling ho kenya letsoho tsamaisong.

Motho ya sehang

Cutter e laoloang ke Siemens PLC e nang le mokhoa oa ho itšeha ka ho feletseng, o ka iketsetsang bolelele ba ho itšeha.

Precision Guide Rail

Sebelisa seporo sa linear guide, cut trolly e tla tsamaea haufi le seporo sa tataiso. Mokhoa oa ho itšeha o tsitsitse le ho itšeha bolelele bo nepahetseng.

'mokelli oa lerole oa indasteri

Ka mokelli oa lerōle oa indasteri o matla bakeng sa khetho ea ho monya lerōle.

Stacker

Ho tšehetsa liphaephe, ka rolara ea tšehetso ea rabara, rolara e tla potoloha hammoho le phala.

Enjene ea rolara

Bakeng sa phala e kholo ea spiral, kenya motlakase ho khanna rolara e potolohang hammoho le phala.

Phetoho ea Bophahamo bo Bohareng

Bakeng sa phala e kholo ea spiral, kenya enjene ho fetola bophahamo ba bohareng, bonolo le kapele.

Lintlha tsa Tekheniki

| Mohlala | Bophahamo ba Lipeipi(mm) | Bokhoni ba Tlhahiso(kg/h) | Kakaretso ea matla(kw) | |

| ID(mets) | OD(max) | |||

| ZKCR800 | 200 | 800 | 100-200 | 165 |

| ZKCR1200 | 400 | 1200 | 150-400 | 195 |

| ZKCR1800 | 800 | 1800 | 300-500 | 320 |

| ZKCR2600 | 1600 | 2600 | 550-650 | 400 |

| ZKCR3200 | 2000 | 3200 | 600-1000 | 550 |

PE carbon spiral matlafatsoa phala extrusion line

| MOHLALA | SJ90/30 | SJ65/30B |

| PIPI DIAMETER | 50-200 | 20-125 |

| KHABANE MOTHO | SGZL-200 | SGZL-125 |

| HLAHALA MACHINA | SLQ-200 | SLQ-200 |

| MOTS'OA MOTS'OA | SQ-200 | SQ-200 |

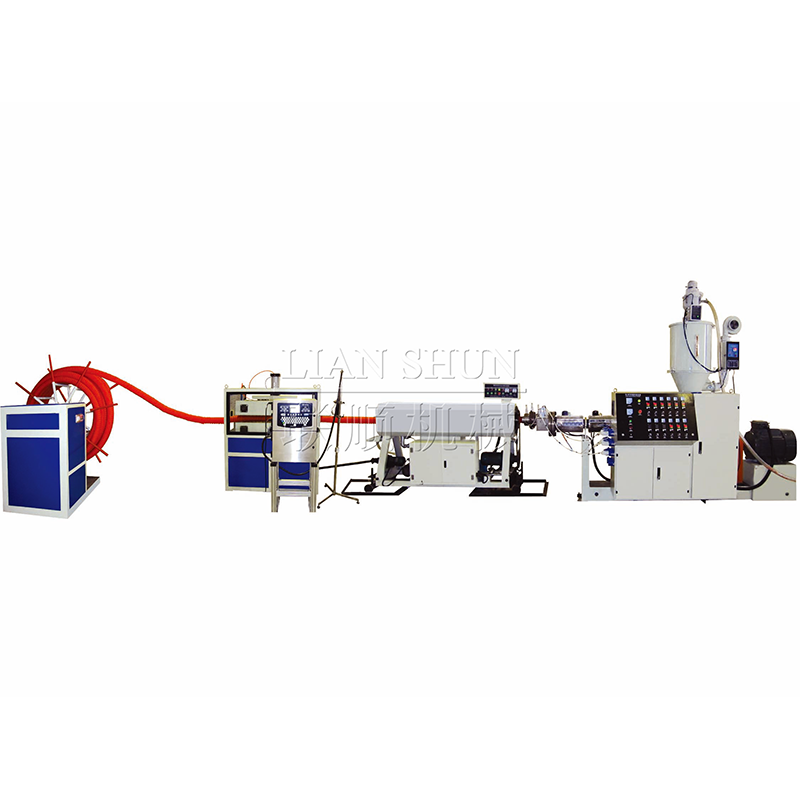

PVC spiral hose extrusion line

| Mohlala | SJ45 | SJ65 |

| Extruder | SJ45/28 | SJ65/28 |

| Range ea Dlameter(mm) | φ12- φ50 | φ63- φ200 |

| Sephetho(kg/h) | 20-40 | 40-75 |

| Matla a kentsoeng(kw) | 35 | 50 |

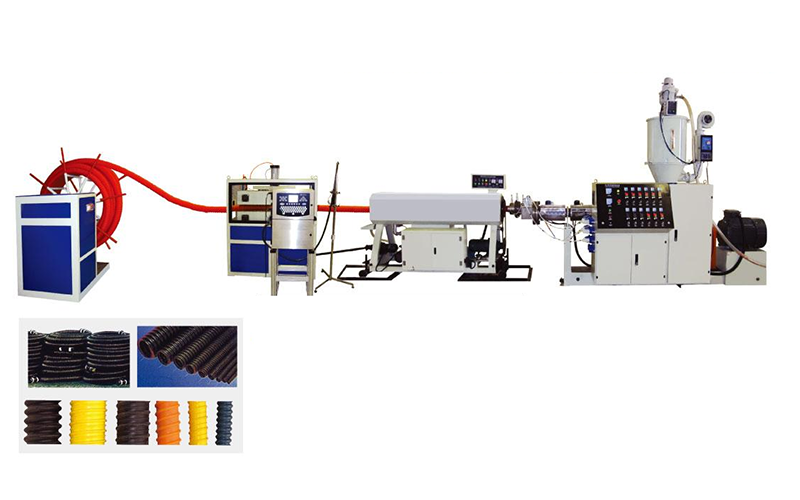

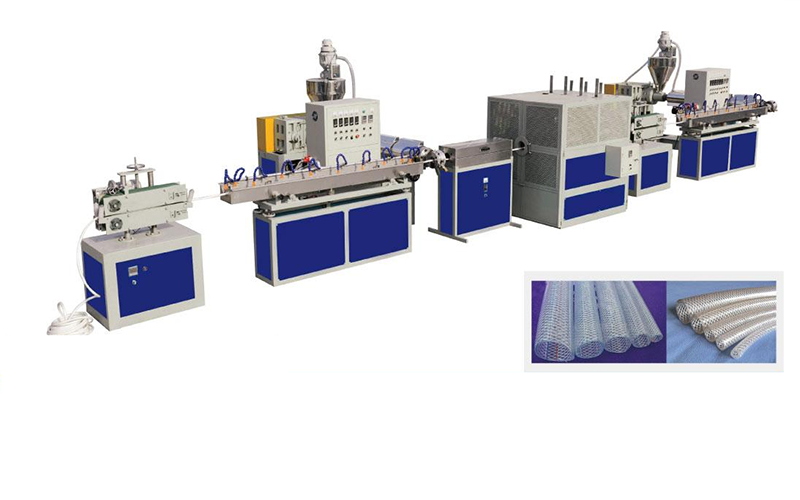

PVC fiber reinforced hose extrusion line

| Extruder | Pipe bophara | Bokhoni | Matla a kentsoeng | Karolelano ea tšebeliso ea matla | boholo |

| SJ-45×30 | <6-25mm | 35-65kg/h | 39.9kw | 27.5kw | 1.2*3*1.4 |

| SJ-65×30 | <8-38mm | 40-80kg/h | 66.3kw | 39.78kw | 1.3*4*5 |

| extruder | Yuniti ea ho hula | Braider | Mochine o pholisang | Tanka e omisang | sefefo |

| 2 lihlopha | 2 lihlopha | 1 sete | 2 lihlopha | 1 sete | 1 sete |

PVC tšepe e matlafalitsoeng hose extrusion line

| Mohlala | SJ45 | SJ65 | SJ90 | SJ120 |

| Extruder | SJ45/30 | SJ65/30 | SJ90/30 | SJ120/30 |

| Range ea Dlameter(mm) | φ12- φ25 | φ20- φ50 | φ50- φ110 | φ75- φ150 |

| Sephetho(kg/h) | 20-40 | 40-75 | 70-130 | 100-150 |

| Matla a kentsoeng(kw) | 30 | 40 | 50 | 75 |