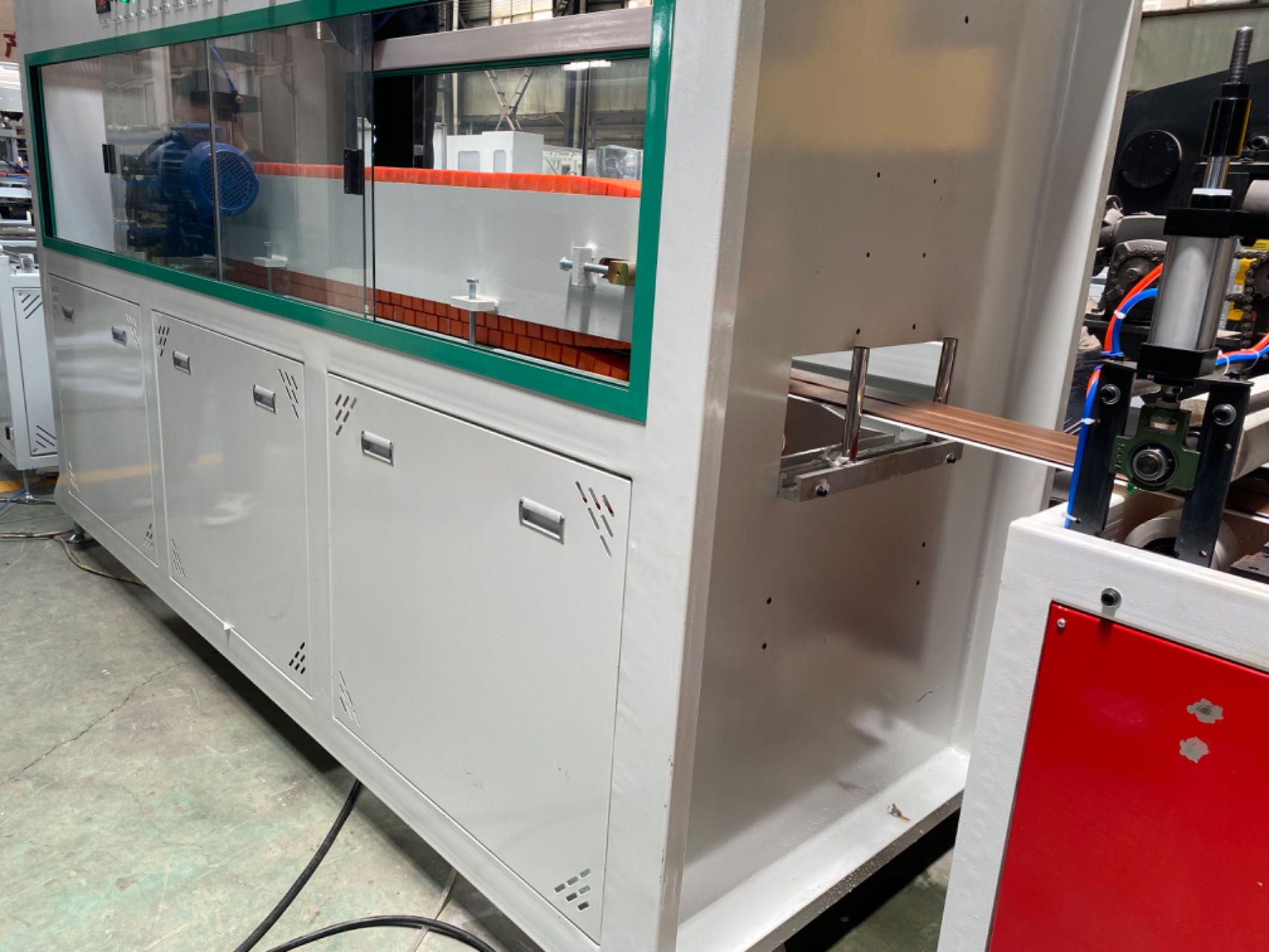

High Output Wood Plastic Profile Extrusion Line

Kopo

Mochini oa Wood Plastic Composite o ile oa boela oa reha mochini oa polasetiki oa lehong, mochini oa wpc, mohala oa tlhahiso ea wpc, mochini oa wpc extrusion, mochini oa tlhahiso oa wpc, mochini oa profil oa wpc, mohala oa tlhahiso ea profil ea wpc, mohala oa wpc profil extrusion joalo-joalo.

Phallo ea Ts'ebetso

PE PP polasetiki ea lehong:

Li-pallets tsa PE / PP + phofo ea lehong + li-additives tse ling (tse sebelisetsoang ho hlahisa thepa ea kaho e khabisitsoeng ka ntle)

Mokhoa oa tlhahiso: Ho sila lehong (phofo ea patsi, raese, lekhapetla) —— Motsoako (polasetiki + phofo ea patsi) ——Mochini oa pelletizing——PE PP wood plastic extrusion line

Plastiki ea lehong ea PVC:

PVC phofo + phofo ea lehong + li-additives tse ling (tse sebelisetsoang ho hlahisa thepa ea mohaho oa ka hare)

Mokhoa oa tlhahiso: Ho siloa ha patsi (phofo ea patsi, raese, lekhapetla) ——Motsoako (polasetiki + phofo ea patsi) ——PVC plastic extrusion line

Melemo

1. Moqomo o futhumetse ka lesale la aluminium, 'me mocheso oa infrared le moea o pholileng o pholile,' me mocheso oa mocheso o potlakile ebile o tšoana.

2. Li-screws tse fapaneng li ka khethoa ho ea ka mekhoa e fapaneng ho finyella phello e ntle ka ho fetisisa ea polasetiki.

3. Lebokose le lecha, lebokose la kabo le amohela li-bearings tse khethehileng, tiiso ea oli e tsoang kantle ho naha, le likere tse sebelisang tšepe ea boleng bo holimo, kalafo ea nitriding.

4. Moralo o khethehileng oa lebokose la li-gearbox, lebokose la kabo, le matlafalitse ho ts'oara, torque e phahameng ea koloi, bophelo bo bolelele ba ts'ebeletso.

5. Tafole ea ho bopa ea Vacuum e amohela ka mokhoa o khethehileng ho eketsa tsamaiso ea hona joale ea ho pholile ea vortex, e loketseng ho pholile, 'me e khethehileng e rapameng e laola taolo e ikhethang ea ho fetola maemo a mararo, ho etsa hore ho be bonolo ho sebetsa hantle.

6. Terekere e sebelisa theknoloji e ikhethang ea ho phahamisa, ho laola le ho theosa le ho laola khatello ea morao, mosebetsi o boreleli, ho tšepahala ho hoholo, ho ts'oaroa ho hoholo, ho itšeha ka mokhoa o itekanetseng, le yuniti ea ho hlaphoheloa lerōle.

Lintlha

Conical Twin Screw Extruder

Ka theknoloji ea morao-rao, ho theola matla le ho netefatsa bokhoni. Ho latela foromo e fapaneng, re fana ka moralo o fapaneng oa screw ho netefatsa phello e ntle ea polasetiki le bokhoni bo phahameng. Li-screws tse fapaneng li ka khethoa ho latela libopeho tse fapaneng ho fihlela phello e ntle ka ho fetisisa ea polasetiki.

Hlobo

Extrusion die head channel ke ka mor'a phekolo ea mocheso, ho bentša seipone le chroming ho netefatsa hore thepa e phalla hantle.

Lebelo le phahameng la ho pholile ho etsa die e ts'ehetsa mohala oa tlhahiso ka lebelo le lebelo le ts'ebetso e phahameng;

. Homogenity e phahameng ea qhibiliha

. Khatello e tlaase e hahiloeng esita le ka lihlahisoa tse phahameng

Tafole ea ho lekanya

Tafole ea calibration e feto-fetoha ka pele-morao, ho le letšehali-le letona, holimo-tlase ho tlisang ts'ebetso e bonolo le e bonolo;

• Kenyelletsa sete e felletseng ea vacuum le pompo ea metsi

• Bolelele ho tloha ho 4m-11.5m;

• Phanele e ikemetseng ea ts'ebetso bakeng sa ts'ebetso e bonolo

Tlosa mochine

Lenala le leng le le leng le na le enjene ea lona ea ho hula, haeba koloi e le 'ngoe e emisa ho sebetsa, likoloi tse ling li ntse li ka sebetsa. E ka khetha koloi ea servo ho ba le matla a maholo a ho hula, lebelo le tsitsitseng haholoanyane le lebelo le pharalletseng la ho hula.

Lenala le leng le le leng le nang le taolo ea khatello ea moea, e nepahetseng haholoanyane, ts'ebetso e bonolo.

Mochini oa seha

Saw cutting unit e tlisa ho itšeha ka potlako le ka mokhoa o tsitsitseng o nang le sekhahla se boreleli. Re boetse re fana ka yuniti e kopantseng ea ho hula le ho seha e leng moralo o momahaneng le o bolokang chelete.

Tracking cutter kapa lifting saw cutter e amohela habeli seteisheneng sa pokello ea lerōle; ho khanna ka mokhoa o lumellanang ka moqomo oa moea kapa taolo ea makoloi a servo.

Lintlha tsa Tekheniki

| Mohlala | SJZ51 | SJZ55 | SJZ65 | SJZ80 |

| Mohlala oa Extruder | Ф51/105 | Ф55/110 | Ф65/132 | Ф80/156 |

| Matla a maholo a moror(kw) | 18 | 22 | 37 | 55 |

| Bokhoni(kg) | 80-100 | 100-150 | 180-300 | 160-250 |

| Bophara ba tlhahiso | 150 limilimithara | 300mm | 400mm | 700 limilimithara |